- Home

- Risks & Protection

- Transformer Explosion Risk

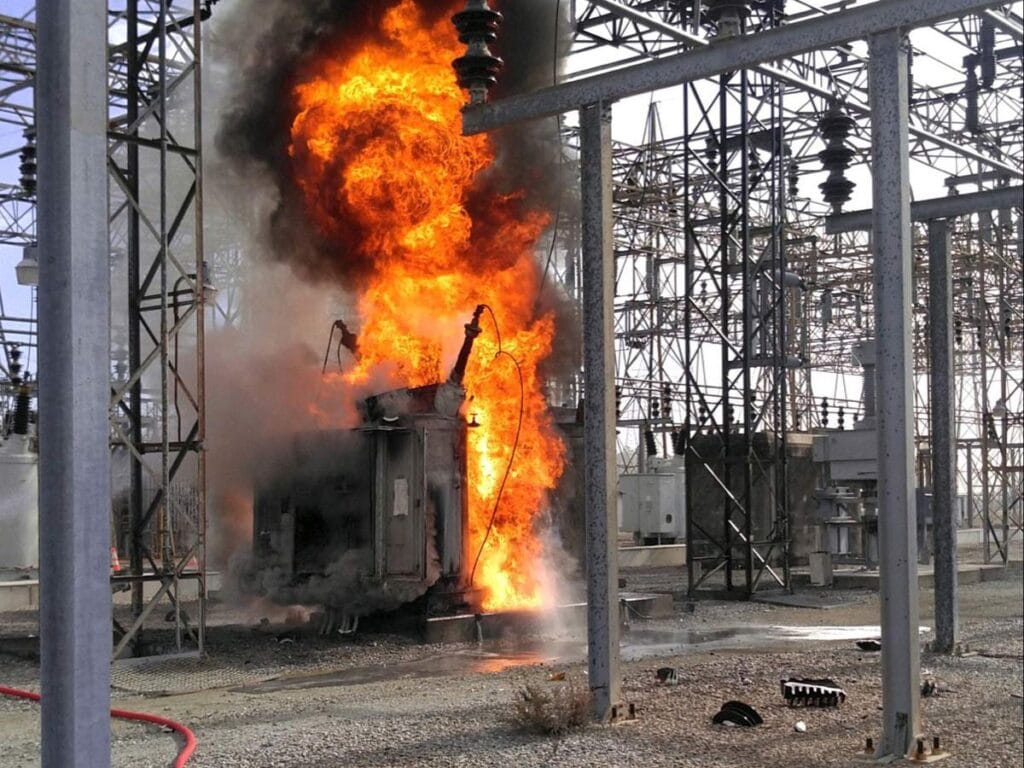

Transformer Explosion Risk

Understanding & Preventing Catastrophic Events

In modern power systems, transformer explosions are low-frequency but high-consequence events. They can escalate locally within milliseconds and—depending on grid configuration and protection coordination—may propagate into wider outages.

What Triggers a Transformer Explosion?

Transformer explosions are not random events — they result from well-identified physical mechanisms that unfold extremely rapidly.

Oil-filled transformers fail when an internal fault occurs — insulation breakdown, mechanical defects, or component failure.

An electric arc vaporizes oil, generating gases and creating a rapid pressure spike that can rupture the tank in milliseconds.

Large power transformers (LPTs) are custom-built assets with long replacement lead times. When they fail, system operators may face prolonged unavailability, constrained capacity and complex recovery logistics.

Identifying the Risks

Transformer explosions are not random events — they result from well-identified physical mechanisms that unfold extremely rapidly.

Consequences of an Explosion

Transformer explosions can result in:

- Severe risk to personnel

- Extensive damage to adjacent equipment and structures

- Prolonged outages and cascading system failures

NFPA 850 is a recommended practice primarily focused on fire risk and escalation control in generating plants and high-voltage installations. It discusses transformer failure scenarios where rapid pressure rise can drive catastrophic mechanical failure, and notes that additional engineered mitigation measures may be considered depending on risk context and site constraints.

Beyond local damage, these events often trigger cascading outages, prolonged unavailability, and systemic operational disruptions.

Why the First Milliseconds Matter

Explosion prevention is a matter of physics and response time — not detection alone.

NFPA 850 (2020) recognizes fast mechanical depressurization systems as a recommended practice for oil-filled transformers.

Why Conventional Protection Is Not Enough

NFPA 850 (2020) recognizes fast mechanical depressurization systems as a recommended practice for oil-filled transformers.

These systems activate in milliseconds — faster than relays, breakers, or fire suppression — addressing the root cause before catastrophic escalation.

Once pressure exceeds the mechanical limits of the tank, no downstream protection can prevent rupture.

From Risk Understanding to Physical Prevention

Transformer explosion risk cannot be eliminated through monitoring or electrical protection alone.

Effective prevention requires acting on the physical mechanisms of failure — before escalation occurs.

What This Means for Your Site

The relevance of explosion protection depends on transformer design, oil volume, confinement, and proximity to critical assets. These parameters vary significantly between sites.